Your Project Is Safe With Us

Efficient Bulk Material Handling / Engineered to perform.

Copyright 2025 Aceme Industries

Design & Promoted By Hindustan Digital Services

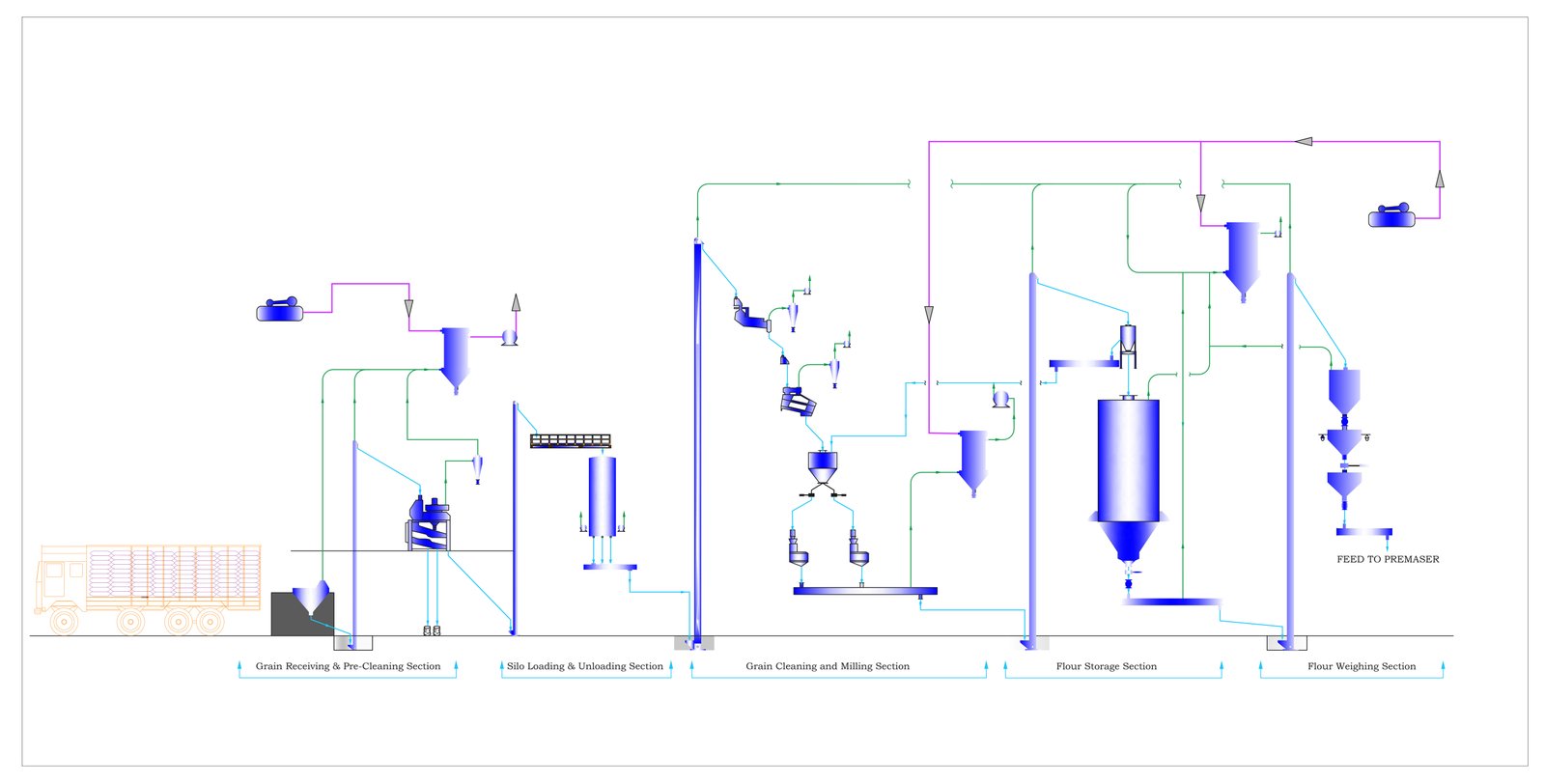

Move grains reliably from intake to storage and processing with minimal loss and dust. We design sealed conveyors and bucket elevators for clean operation, low maintenance, and long service life. From receiving to milling lines, our systems ensure gentle transfer, accurate flow control, and easy access for inspection and cleaning. You get predictable throughput, safer workplaces, and faster turnaround on maintenance. Built in SS/MS as required with food-grade options and global-standard safety.

Capacity: Up to 500 TPH

Automate fuel movement from truck/wagon unloading to boiler feeding—crushing, screening, tramp removal, conveying, and metered feeding. Our sealed systems reduce spillages and fire risk, while variable-speed drives and feeders stabilise combustion for better boiler efficiency. Rugged design handles abrasive fuels with ease and simplifies upkeep through modular components. You get consistent fuel flow, cleaner yards, and lower operating cost per ton. Integrated magnets, metal detectors, and dust control are available.

Capacity: Up to 500 TPH

Engineered for distilleries, our solutions handle wet cake (DWGS) to dried DDGS without caking, bridging, or segregation. Gentle transfer preserves nutrition value and reduces fines, while lined chutes, slow-speed conveyors, and controlled discharge keep product moving. Sanitary design with easy wash-down and access points shortens changeovers and improves hygiene. Level monitoring and flow aids ensure steady loading of storage and trucks. You get dependable flow and cleaner operations.

Capacity: 50 TPH

From paddy intake to finished rice, we integrate conveying, aspiration, and dust control to protect product quality and reduce breakage. Our systems link cleaning, dehusking, polishing, grading, and packing with minimal transfer points. Sealed conveyors, soft transitions, and precise flow control deliver a safer, cleaner, and more efficient mill. Maintenance access and wear-resistant parts keep downtime low. You get stable throughput and superior finished rice.

Capacity: 00 TPH (Paddy) | 150 TPH (Rice)

Built for oily, abrasive materials, our conveyors support cleaning, crushing, extraction, and meal handling with robust construction and precise sealing. Optional food-grade designs and stainless steels maintain hygiene where needed. Anti-spillage features, wear liners, and accessible bearings reduce maintenance and extend service life. Integrated magnets and sifters improve process reliability. You get clean transfer, fewer stoppages, and safer working areas across your mill.

Capacity: 200 TPH

Automate ash movement from boiler and ESP to silos or disposal—extraction, conveying, conditioning, storage, and truck loading. Our sealed systems control dust and spillage, with wear-resistant liners and slow-speed equipment for abrasive ash. Options include dense-phase pneumatic for long routes, submerged chain/bottom-ash conveyors for reliable silo reclaim. You get cleaner yards, predictable ash evacuation, and lower cost per ton.

Capacity: Up to 20 TPH

Lean- and dense-phase solutions move powders and granules over long routes with closed, dust-free conveying. Smart valve sequencing, air management, and filtration deliver stable flow and low product degradation. Ideal where hygiene, routing flexibility, or space is a constraint. Skid-mounted packages simplify installation and maintenance. You get automation-ready conveying that protects quality and keeps floors clean—integrated with your PLC/SCADA.

Capacity: Project-specific (typical 2–10 TPH)

Capture fugitive dust at transfer points and process equipment to improve air quality and safety. We engineer hoods, ducts, cyclones, and bag filters with correct velocities, pressure balance, and emissions control. Access doors, hopper discharge aids, and pulse-jet cleaning keep systems running at peak efficiency. You get compliance-ready emissions, cleaner plants, and longer equipment life. Integration with conveyors, screens, and mills ensures end-to-end performance.

Capacity: Air volume typical 5,000–22,000 m³/hr

Flat warehouses and steel silos for grains, meals, and powders—engineered for safe storage, first-in-first-out reclaim, and minimal losses. Aeration, temperature/level monitoring, sweep augers, and flow-aids maintain grain health and reduce caking. Our reclaim solutions are designed to pair with your downstream process for a steady discharge. You get reliable inventory, faster loading/unloading, and lower lifecycle cost. Designed to relevant codes with turnkey erection and commissioning.

Capacity: Up to 120 MT (Flour)